Robotics Transforming Manufacturing

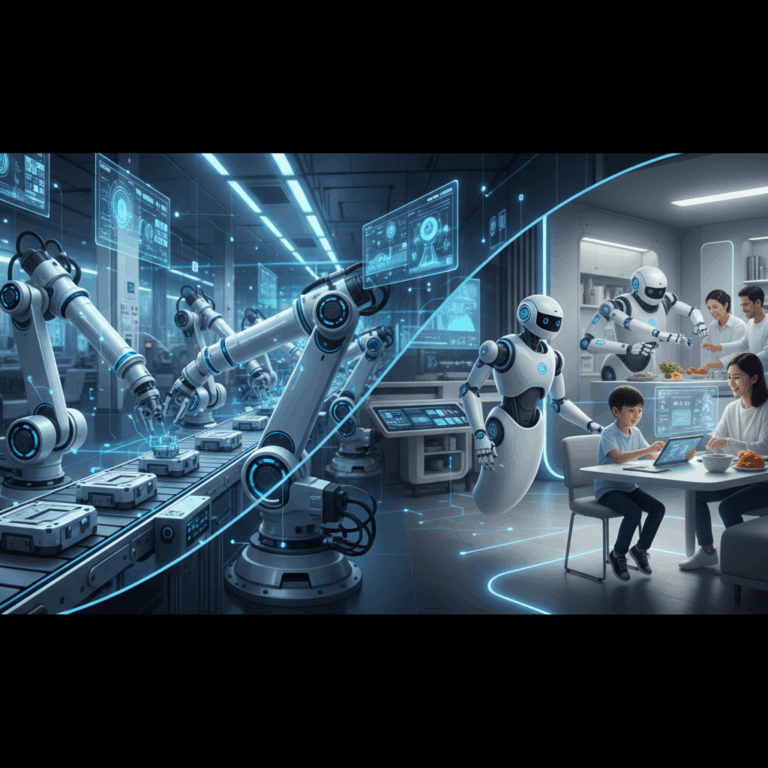

The field of manufacturing has witnessed a significant shift due to robotics innovations. Advanced robots are now more accessible, allowing manufacturers to enhance their operations effectively.

This accessibility enables small and mid-sized companies to compete globally by integrating intelligent automation systems into their production lines.

Advanced Robots Accessible for All Manufacturers

Robots once limited to large factories are becoming affordable and adaptable for all manufacturers. This democratization allows more businesses to implement high-tech solutions.

These advanced machines perform tasks like welding, assembly, and packaging accurately, ensuring consistent output while reducing manual labor dependency.

By lowering the cost barrier, robotics technology supports diverse industries, from automotive to electronics, improving efficiency at all production scales.

Impact on Productivity and Worker Safety

Robotic automation significantly boosts productivity by allowing continuous operation and minimizing errors through precision tasks.

Moreover, robots handle dangerous or repetitive jobs, reducing workplace injuries and creating a safer environment for employees.

This dual benefit of higher output and improved safety helps companies maintain competitive advantages while promoting worker well-being.

Workforce and Economic Effects of Robotics

The integration of robotics in industries addresses critical labor shortages by providing efficient automation solutions. These machines help reduce costs and enhance operational continuity.

Robotics also reshape the labor market by introducing new collaborative roles, where humans work alongside machines to optimize productivity and innovation.

Addressing Labor Shortages and Cost Reduction

Robots compensate for the lack of skilled workers, ensuring continuous production without fatigue or errors. This is vital amid rising wages and tight labor markets.

Investment in robotics yields quick returns by lowering labor expenses and enabling 24/7 operations, which helps companies stay competitive globally.

Moreover, these automated systems handle repetitive and hazardous tasks, freeing human workers for more complex and value-driven roles.

Collaborative Robots and Human Workforce Integration

Collaborative robots, or cobots, work safely alongside humans, complementing their efforts rather than replacing them. This synergy enhances productivity.

Cobots are designed to assist with tasks requiring precision and consistency while allowing human workers to focus on decision-making and creative problem-solving.

This co-working model fosters a balanced environment where human skills and robotic efficiency combine to improve overall workflow and job satisfaction.

New Job Roles in Robotics Management

The rise of robotics generates demand for new roles such as robot maintenance, programming, and systems optimization, requiring technical expertise.

Workforce development efforts focus on training employees to manage and enhance robotic systems, integrating artificial intelligence for improved performance.

Emerging Careers in Robotics

Roles in AI integration and machine learning are growing, with specialists needed to ensure robots adapt and function reliably in dynamic industrial settings.

Robotics in Daily Personal Life

Robotics innovations are increasingly present in daily personal life, transforming household tasks and enhancing convenience. Smart robots handle routine chores efficiently.

From cleaning to yard work, these machines free up valuable time, allowing people to focus on more meaningful activities and improving overall quality of life.

Household Automation and Convenience

Robots like automated vacuum cleaners and lawn mowers are becoming common, reducing the effort needed for house maintenance. Their autonomous nature ensures chores get done consistently.

These devices offer convenience by adapting to home environments and schedules, making household management less stressful and more efficient for users.

Integration with smart home systems further enhances their capabilities, allowing voice control and remote operation through mobile apps for greater usability.

Future Prospects with Adaptive Robotics and 3D Printing

The future of personal robotics will be shaped by adaptive technologies and 3D printing, enabling customized solutions created on-demand within households.

Adaptive robots can learn user preferences and adjust tasks accordingly, providing personalized assistance that evolves with daily routines and needs.

On-Demand Manufacturing at Home

Combining robotics with 3D printing technology promises to revolutionize home production, allowing users to fabricate tools, parts, or even toys without external suppliers.

This innovation could reduce waste, lower costs, and promote creativity, while also empowering individuals to solve problems quickly using tailored robotic solutions.

Challenges and Opportunities in Robotics

As robotics technology advances, workforce development becomes crucial. Workers must acquire new skills to operate, maintain, and innovate alongside intelligent machines.

This evolution presents opportunities for lifelong learning but also challenges in training an adaptable workforce ready for a tech-driven environment.

Workforce Development and Skill Requirements

The rise of smart robots demands that employees gain technical skills in programming, system management, and AI integration to stay relevant.

Companies need to invest in continuous training programs, fostering an environment where human talent and robotic systems effectively collaborate.

Adapting educational curricula to include robotics and automation prepares future workers for emerging roles that emphasize creativity and complex problem-solving.

Societal Impact and Human-Machine Collaboration

Robotics are reshaping society by creating new forms of collaboration where humans and machines work as partners rather than competitors.

This shift enhances productivity, safety, and personalized experiences while raising important questions about ethics, privacy, and workforce displacement.

Balancing technological benefits with social responsibility involves developing policies that support equitable access to robotics innovations.